Different lasers for crystal inner engraving

For laser machines, crystal inner engraving is a very special application. As most laser machines can't deal with transparent materials, only two lasers are exceptions: the 532nm and the 355nm. Or, we call them the green laser and the UV laser.

One basic knowledge recall: laser crystal inner engraving is to make a tiny crack on the crystal.

So, different forms of cracks give different performance for the crystal engraving effect. And the forms of the crack depend on the laser source box and the laser path.

First, the laser source box decides whether the crack is large or small, which means big dots or small dots. That will influence the resolution of the image you get. Of course, the smaller, the better.

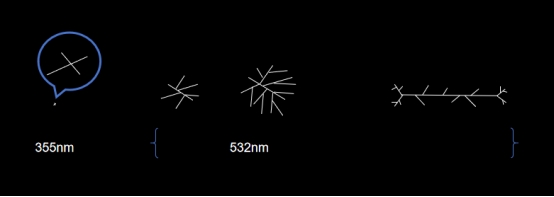

Observe under a microscope:

If we divide the laser source box according to the crack form, we need to first divide the UV laser and the green laser. Because the UV laser makes much smaller dots, while the green laser gives much bigger dots.

So if the UV laser wants to make the same bright dots as the green laser, it needs much more time, and the laser needs to hit it several times. That is why the UV laser machine in the market gives a light image, or it needs a lot of time to make an image.

All investors who want to do crystal business care about the production speed, so they would never choose the UV laser; the green laser is their only choice.

However, the green laser source is much expensive than UV laser source, so the green laser machine also expensive then the UV laser machine.

A deeper look at green lasers.

Not all green lasers are suitable for inner engraving.

When the laser production principles are different, the beam parameters produced will also be different. Even for laser source boxes of the same design, the beam parameters produced will also be different if the quality of the components used is different. Then the crack forms are different.

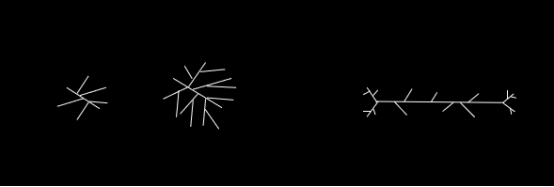

There I show you three different crack forms produced by different green laser sources box.

These three kind of cracks can been used to make three different effect of image.

The first and second points are more concentrated, the third is more spread out.

So the first crack can make high resolution of the image.

The second crack let the image more brighter

While the third crack will not be very bright.

These three kinds of cracks can be used to give three different effects to the image.

The first and second points are more concentrated, the third is more spread out.

So the first crack can make a high resolution of the image.

The second crack made the image brighter

While the third crack is too separate that the image is shallow.

In the market, the first and second points are more concentrated, they can make a more beautiful image. So, the green laser source to make this kind of crack is more expensive, therefore, this kind of green laser machine is more expensive.

English

English Chinese

Chinese