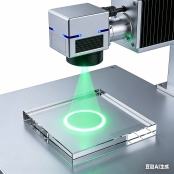

Lens single engraving area and the machine engraving area

Today’s sharing is about the machine details and the machine differences.

When we see the machine, we will see the machine engraving area, and sometimes, we will also see the lens single engraving area. So what is the difference?

Machine engraving area refers to the max crystal size, which means you can put that size of crystal on the machine and engrave a big image in it.

And the lens single scan area means that if there is no movable plate, the machine can only do that area. And the lens's single scan area is usually not very big, according to the lens technology limit.

Usually, it is like that, every machine have the single scan area. That area will not be very big, and if the machine wants to do a bigger area, then we will use the moveable plat. To do the big image, we will divide the machine into many small parts ( which are smaller than the single scan area ), then we engrave one part, move the plate, engrave another part, and then....

Finally, we will get a big image by using this method.

However, when you know this process, you will quickly realize one question. Can the machine combine every part well and give a good effect?

This kind of concern is due to two points.

First, laser dots are a very tiny thing; the whole image is combine by the tiny dots. So let every dot in the right position is very important for the image. Second, the movable plate is a mechanical structure. It inevitably contains Tolerances. Tolerances is inherent in every measuring instrument.

These two points are actually when there are gaps and lines in the big image.

Knowing the reason, we can find the solution based on it.

So there are two paths to avoid it. First, make the single area bigger; second, reduce the Tolerance.

These refer to two paths: a better lens or a better movable plate.

For the first path, use the better lens (bigger scan area lens). For today’s technology, the normal lens scan area is about 70mm, 90mm, or 120mm. If we need a bigger scan area lens than these, the technology request and cost request will have huge differences; some can only rely on Germany supplier. That cost is more than ten times than the normal lens. However, it actually can achieve a better engraving quality. With our special laser source box and imported German lens, we can do max 200mm single scan area. That is enough for most of the crystal sizes.

For the second path, use a better movable platform. A movable plat is a mechanical system. That system includes the motors, lead screw, guide rail, and so on. Normally, most of the start level machines will use Chinese stepper motor and the Chinese-made lead screw and components. If you want to get better engraving quality for big size machine, you need to use better components. According to our study and practice, we have select some high quality components suitable for our the machine. This kind of high quality machine have special functions, and they are suitable for the business man who are seriously for the crystal 3d gift business and want be the top supplier in the market.

Besides this two method, we also have a special solution, by changing the position of dots using special software function, Tolerances in the mechanical structure can be compensated. This special compensation method is a special algorithm developed by our engineers through years of research and practice. We develop our own software, and many of our features are based on practical testing, giving us a unique advantage in the market.

Usually, we see that a machine can do 300*400mm, the “300*400mm” is the machine engraving area, not the lens single scan area, the lens single scan area for this kind of machine is usually about 90mm or 120mm. That is a kind of start level machine. Different machines use difference parts have difference function and give different effect. So when study one type of machine, focus on the machine details and what kind of components they use.

English

English Chinese

Chinese