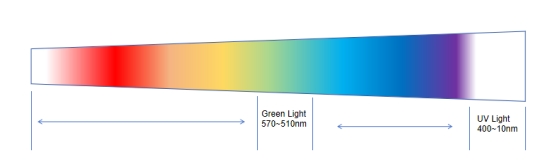

Laser technology has become an indispensable tool due to its high precision, high efficiency, and non-contact processing characteristics. Among the many types of laser sources, UV laser and green laser have shown unique applications in the field of glass processing due to their unique optical properties. This article will introduce the differences between these two lasers in glass processing applications.

UV laser and glass surface marking

The UV laser with a wavelength of 355nm has excellent performance in the field of glass surface marking due to its short wavelength and high energy density. When the UV laser beam is irradiated on the glass surface, its high energy density can quickly heat a small area on the glass surface, causing the surface of the material to melt or vaporize locally. By controlling the motion trajectory and energy distribution of the laser beam, various complex marks such as text, patterns, and QR codes can be accurately formed.

UV laser marking technology has many advantages. First, due to the short wavelength of a UV laser, its focused spot size is small, which can achieve more delicate markings. Secondly, the UV laser has a short action time with the glass surface, a small heat-affected zone, and almost no thermal damage or deformation to the glass surface. In addition, UV laser marking also has the advantages of fast speed, high efficiency, environmental protection, and no pollution.

UV laser marking technology is widely used on glass packaging bottles in cosmetics, pharmaceuticals, food, and other industries. Through UV laser marking, clear production date, batch number, QR code, and other information can be printed on the bottle, which is convenient for consumers to query and identify, without damaging the packaging and medical devices, and has great development potential.

Green laser and glass inner engraving 3D engraving

Unlike UV laser, green laser has unique advantages in glass inner engraving and 3D engraving. The wavelength of a green laser is 355nm, which is longer and can penetrate the surface of glass and form a focus inside. When the green laser beam is irradiated to the inside of the glass, its energy will be absorbed by the glass material and converted into heat energy, resulting in local melting or gasification of the material. By controlling the motion trajectory and energy distribution of the laser beam, complex three-dimensional patterns or text can be formed inside the glass.

Due to the strong penetration of green laser, it can be engraved inside thicker glass. At present, green laser engraving technology is mainly used for personalized customization of gifts, souvenirs, and decorations. Due to the uniqueness and exquisiteness of the crafts, they are widely used and have high profits. You only need one machine to start your own business.

Summary

Ultraviolet laser and green laser each have their own unique application areas in the glass processing industry. Ultraviolet laser has a short wavelength and high energy density, which is suitable for fine marking on the glass surface; while green laser has a long wavelength and strong penetration, which is suitable for 3D engraving inside the glass.

https://www.crystal3dlaser.com/products.html

English

English Chinese

Chinese