How our machine catch and over the classical high level machine?

Today’s post is like a report, to show how our technology has developed, improved, and gained a unique advantage over other classical machines.

Decades ago, when our founder first came into contact with green lasers, the green laser engraving machine at that time only completed the engraving of patterns on the crystal. The patterns at that time were very rough, and the engraving speed was very slow.

After many years of development, we started with lasers and developed them little by little. Now we have developed a better laser source box, better software, better laser control card, and better scanner. For some other core parts, like the motor, we select good-quality and suitable-sized motors from around the world. So, let me report our advantages over the classical high-level machine. And that is also the success of our more than ten years of research and development.

You may see in the market that the old classical machine with very expensive. And they give you some advantages that other machines in the market can’t reach. Anyway, we have to admit that these advantages are great. However, we still want to develop our own technology according to our customers’ demands.

The classical machine engraves very fast, but its image is very light no matter fast engraving and slow engraving. That is because it uses the YVO4 laser source, the power of this laser source is not strong. So the crystal must be shown with the light base, or it can’t catch the customer’s eyes.

So to help our customers engrave brighter and attractive images, we develop a new type of green laser source. In this laser box, we use YAG to strengthen the power of the laser. This makes the image very bright, even without the light base, it can easily catch the eyes of customers.

However, to improve the engraving speed, we also give our own special solution, not just increasing the laser frequency and reducing the image brightness.

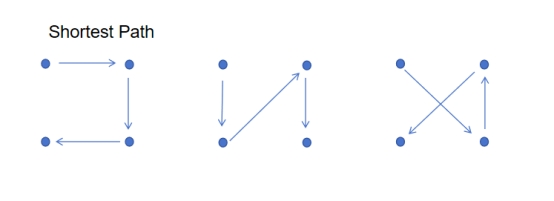

First, we wrote the algorithm to optimize the motion path of the galvanometer. We all know that the dots for an image are not a line; when the galvanometer works with the tortuous path, the laser doesn’t work all the time. Sometimes, the laser needs to wait for the galvanometer to move to the right position. So, we try to reduce the time and let the galvanometer walk on the shortest path.

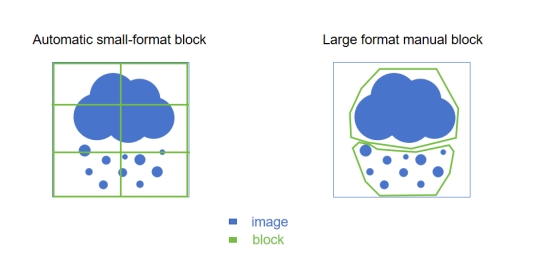

For big image engraving, we have also developed our own solution to increase the engraving speed. The main factor that affects the engraving speed of the big image engraving is that they need to do splicing work. Cut the image into small blocks and engrave them one by one. So we give two methods to solve this problem. First, give more scan range to one block, the one we need to change the hard part of the machine; second, add the manual block-making function.

This is part of the result of our long-term research and development. We always listen to customers' demands and use technological updates to help customers get a better user experience.

With our strong technology team, our after-sales service is excellent. Our experienced engineer team will quickly help you find the problem and solve the problem with a short video call.

English

English Chinese

Chinese